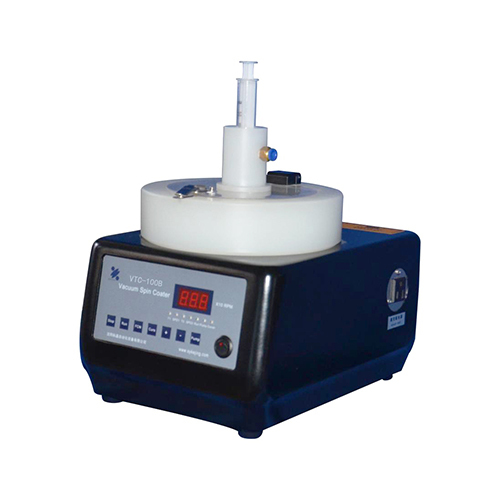

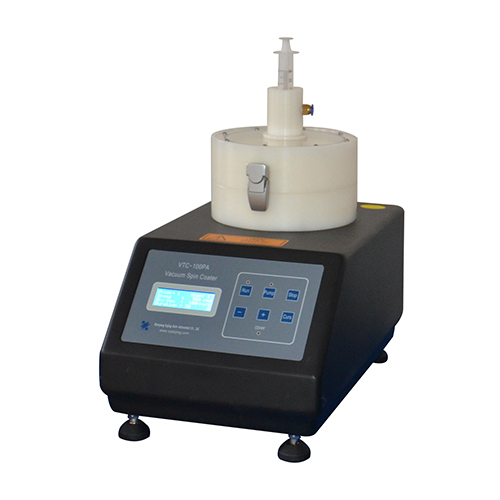

Programozható vákuumos tokmányos forgó bevonatoló (500-6000 fordulat/perc, 8" max.)

A VTC-200 vákuumos centrifugális bevonatoló berendezés előnyei az egyszerű kezelhetőség, a könnyű tisztíthatóság és a kis méret. Főként főiskolák, egyetemek és tudományos kutatóintézetek laboratóriumaiban használják filmnövesztő folyamatokban. Működés közben a VTC-200 vákuumos centrifugális bevonatoló berendezés vákuumlemezes adszorpciós módszert alkalmaz a minta mintalemezre történő rögzítéséhez. A berendezés kétlépcsős programot használ a sebesség szabályozására.

- Shenyang Kejing

- Senjang, Kína

- 10 munkanap

- 50 szett

- információ

Termékbemutató

A VTC-200 vákuumos centrifugális bevonatoló gép egyszerű kezelhetőséggel, kényelmes tisztítással és kompakt kialakítással rendelkezik. Főként egyetemi és kutatóintézeti laboratóriumokban használják vékonyréteg-készítéshez.

Működés közben a VTC-200 vákuumszívással rögzíti a mintát a tokmányra. A készülék kétlépcsős programot alkalmaz a forgási sebesség szabályozására. Az első lépésben a centrifugálási sebességet egy adott tartományon belül állítják be, és egy meghatározott adagolási időt alkalmaznak az oldat mintára csepegtetéséhez. Az adagolás után a bevonatoló gép a centrifugális bevonás második fokozatának maximális sebességére gyorsul. A centrifugális bevonás előtt be kell állítani a bevonási időt; a folyamat befejezése után a gép automatikusan leáll.

A VTC-200 vákuumos centrifugális bevonatoló nagy sebességű forgást használ a viszkózus kolloidok, oldatok és más folyékony anyagok egyenletes bevonására a minta felületén.

Főbb jellemzők

1. A sebességet egy kétlépcsős program szabályozza.

2. A mintát vákuumadszorpcióval rögzítik, ami könnyen kezelhető.

3. Öntött alumínium szerkezet, stabil működés és alacsony zajszint

TMűszaki paraméterek

Termék neve | VTC-200 vákuumos centrifugális bevonatoló | |

Termékmodell | VTC-200 | |

Telepítési feltételek | 1. Hőmérséklet és páratartalom: 10-85% relatív páratartalom (25 ℃-on, páralecsapódás nélkül) Hőmérséklet: 0-45 ℃. 2. A berendezés körül nincs erős rezgésforrás és korrozív gáz. 3. Víz: Nem szükséges 4. Elektromosság: Egyfázisú: AC220V 50Hz. 5. Gáz: Vákuum negatív nyomás (vákuumszivattyú) kipufogógáz áramlási sebessége nem kevesebb, mint 70L/perc 6. Munkapad: 800 mm × 600mm×700 mm-es ajánlott teherbírás 100 kg vagy több (a tömör cementplatform jobb) 7. Szellőztetőberendezés: Nincsenek különleges követelmények | |

Fő paraméterek (Specifikáció) | 1. Tápegység csatlakozója: Biztosított hálózati aljzat: AC220/110V 50/60Hz, biztosítócső specifikációja 10A, φ5 × 20mm 2. Teljes teljesítmény: ≤150W 3. Mintatartó tálca (tapadókorong + terelőlap): φ153 mm-es polipropilén vákuumos tapadókorong 1 darab: 6 hüvelykes (φ153 mm) mintaterelő 1 készlet 8 hüvelykes (φ203,5 mm) mintaterelő 1 készlet 4. Működési mód: két üzemmóddal, az óramutató járásával ellentétes irányú forgás 5. Bevonatolási sebesség: SPD1 sebesség: 500-6000 fordulat/perc effektív SPD2 sebesség: 500-6000 effektív fordulat/perc 6. Bevonatolási idő: T1 idő: 1–600 s effektív T2 idő: 1-600 s effektív 7. Sebességstabilitás: ±1% 8. Vezérlési mód: NYÁK egychipes mikrokomputeres kulcsvezérlés Digitális csőkijelző | |

9. Termékleírás · Méret: 500 mm × 350 mm × 400 mm · Súly: 30 kg |

| |

Sstandard kiegészítők

Nem. | név | mennyiség | kép |

1 | Vákuum tokmány (Ø153mm) | 1 db | - |

2 | Injektor/fecskendő | 1 db | - |

3 | Olajmentes vákuumszivattyú | 1 db |

|

Aopcionális kiegészítők

Nem. | név | funkcionális típus | kép |

1 | Szűrő (vákuumszivattyúhoz) | (választható) | - |

2 | Pipetta (Kínában készült) | (választható) |

|

3 | Pipetta (importált) | (választható) |

|

Garancia

Egy év korlátozott élettartamra szóló támogatással (a nem megfelelő tárolási körülmények miatt rozsdásodott alkatrészek kivételével)

Logisztika